Review of Pretreatment of Reverse Osmosis Seawater Desalination

DOI:

https://doi.org/10.70516/w1bfpg35Keywords:

Coagulation, Desalination, Low-pressure membrane, Pretreatment, Reverse osmosisAbstract

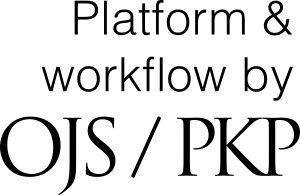

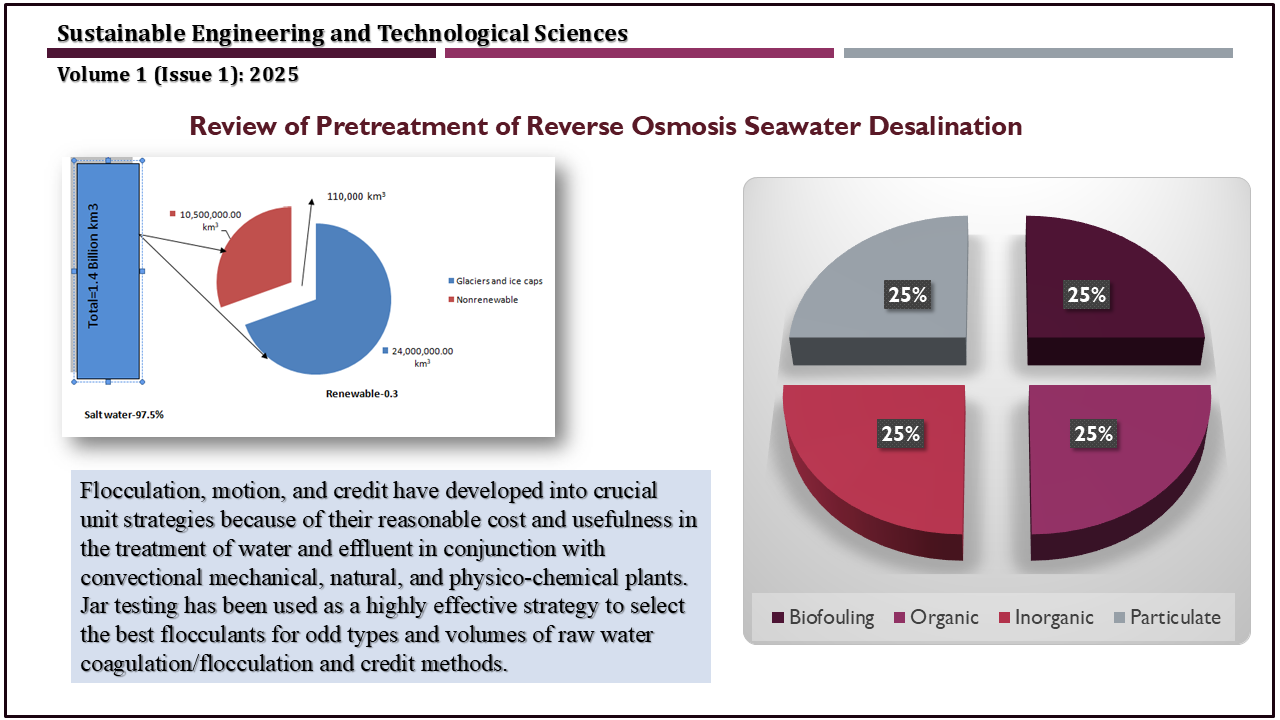

Over the past decade, the age-old and peaceful method of membrane preprocessing has seen a markedly accelerated improvement in its usefulness for artificial speech naturalness. Profitable operation of the SWRO process requires a reliable pretreatment method as the main disadvantages are membrane fouling related to particles, organic, inorganic colloids material and organic growth. The older pre-treatment methods like active and particulate filtration are widely used in seawater desalination by RO techniques; there is a growing trend to use ultrafiltration/microfiltration as an alternative to older treatment technologies. Research highlights that both mass-based methods and UF/MF membrane pretreatment techniques offer distinct benefits and limitations. This evaluation shows that, given the excellent condition of the feed water, an appropriate integration of 1 or 2 pretreatment technologies can also be considered justified, as this can benefit from each individual pretreatment.

Downloads

References

Greenlee LF, Lawler DF, Freeman BD, Marrot B, Moulin P. Reverse osmosis desalination: water sources, technology, and today's challenges. Water Res. 2009;43:2317-2348.

Brehant A, Bonnelye V, Perez M. Comparison of MF/UF pretreatment with conventional filtration prior to RO membranes for surface seawater desalination.Desalination 2002;144:353-360. DOI: https://doi.org/10.1016/S0011-9164(02)00343-0

Reverter JA, Talo S, Alday J. Las Palmas III - the success story of brine staging. Desalination 2001;138:207-217. DOI: https://doi.org/10.1016/S0011-9164(01)00266-1

Reverberi F, Gorenflo A. Three year operational experience of a spiral-wound SWRO system with a high fouling potential feed water. Desalination 2007;203:100-106. DOI: https://doi.org/10.1016/j.desal.2006.05.005

Tran T, Bolto B, Gray S, Hoang M, Ostarcevic E. An autopsy study of a fouled reverse osmosis membrane element used in a brackish water treatment plant. Water Res. 2007;41:3915-3923. DOI: https://doi.org/10.1016/j.watres.2007.06.008

Magara Y, Kawasaki M, Sekino M, Yamamura H. Development of reverse osmosis membrane seawater desalination in Japan. Water Sci. Technol. 2000;41:1-8. DOI: https://doi.org/10.2166/wst.2000.0594

Her N, Amy G, Chung J, Yoon J, Yoon Y. Characterizing dissolved organic matter and evaluating associated nanofiltration membrane fouling. Chemosphere 2008;70:495-502. DOI: https://doi.org/10.1016/j.chemosphere.2007.06.025

Yoon J, Yoon Y, Amy G, Her N. Determination of perchlorate rejection and associated inorganic fouling (scaling) for reverse osmosis and nanofiltration membranes under various operating conditions. J. Environ. Eng. 2005;131:726-733. DOI: https://doi.org/10.1061/(ASCE)0733-9372(2005)131:5(726)

Lee H, Amy G, Cho J, Yoon Y, Moon SH, Kim IS. Cleaning strategies for flux recovery of an ultrafiltration membrane fouled by natural organic matter. Water Res. 2001;35:3301-3308. DOI: https://doi.org/10.1016/S0043-1354(01)00063-X

Abdessemed D, Nezzal G. Coupling softening – ultrafiltration like pretreatment of sea water case study of the Corso plant desalination (Algiers). Desalination 2008;221:107-113. DOI: https://doi.org/10.1016/j.desal.2007.01.072

Bonnelye V, Sanz MA, Durand JP, Plasse L, Gueguen F, Mazounie P. Reverse osmosis on open intake seawater: pretreatment strategy. Desalination 2004;167:191-200. DOI: https://doi.org/10.1016/j.desal.2004.06.128

Burashid K, Hussain AR. Seawater RO plant operation and maintenance experience: Addur desalination plant operation assessment. Desalination 2004;165:11-22. DOI: https://doi.org/10.1016/j.desal.2004.06.002

Chua KT, Hawlader MN, Malek A. Pretreatment of seawater: results of pilot trials in Singapore. Desalination 2003;159:225-243. DOI: https://doi.org/10.1016/S0011-9164(03)90075-0

Ebrahim S, Abdel-Jawad M, Bou-Hamad S, Safar M. Fifteen years of R&D program in seawater desalination at KISR Part I. Pretreatment technologies for RO systems. Desalination 2001;135:141-153. DOI: https://doi.org/10.1016/S0011-9164(01)00146-1

Glueckstern P, Priel M, Wilf M. Field evaluation of capillary UF technology as a pretreatment for large seawater RO systems. Desalination 2002;147:55-62.

Pervov AG, Andrianov AP, Efremov RV, Desyatov AV, Baranov AE. A new solution for the Caspian Sea desalination: lowpressure membranes. Desalination 2003;157:377-384. DOI: https://doi.org/10.1016/S0011-9164(03)00420-X

Van Hoof SC, Hashim A, Kordes AJ. The effect of ultrafiltration as pretreatment to reverse osmosis in wastewater reuse and seawater desalination applications. Desalination 1999;124:231-242. DOI: https://doi.org/10.1016/S0011-9164(99)00108-3

Xu J, Ruan G, Chu X, Yao Y, Su B, Gao C. A pilot study of UF pretreatment without any chemicals for SWRO desalination in China. Desalination 2007;207:216-226. DOI: https://doi.org/10.1016/j.desal.2006.08.006

Sinha S, Yoon Y, Amy G, Yoon J. Determining the effectiveness of conventional and alternative coagulants through effective characterization schemes. Chemosphere 2004;57:1115-1122. DOI: https://doi.org/10.1016/j.chemosphere.2004.08.012

Khawaji AD, Kutubkhanah IK, Wie JM. A 13.3 MGD seawater RO desalination plant for Yanbu Industrial City. Desalination 2007;203:176-188. DOI: https://doi.org/10.1016/j.desal.2006.02.018

Bache DH, Gregory R. Flocs and separation processes in drinking water treatment: a review. J. Water Supply Res. Technol. AQUA 2010;59:16-30. DOI: https://doi.org/10.2166/aqua.2010.028

Wilf M, Bartels C. Integrated membrane desalination systems--current status and projected development [Internet]. 2006. Available from: http://www.membranes.com/docs/papers/New%20Folder/Abstract%20for%20Tianjin%20-%20Hydranautics.pdf.

Choi KY, Dempsey BA. In-line coagulation with low-pressure membrane filtration. Water Res. 2004;38:4271-4281. DOI: https://doi.org/10.1016/j.watres.2004.08.006

Gabelich CJ, Yun TI, Coffey BM, Suffet IH. Effects of aluminum sulfate and ferric chloride coagulant residuals on polyamide membrane performance. Desalination 2002;150:15-30. DOI: https://doi.org/10.1016/S0011-9164(02)00926-8

Gabelich CJ, Williams MD, Rahardianto A, Franklin JC, Cohen Y. High-recovery reverse osmosis desalination using intermediate chemical demineralization. J. Membr. Sci. 2007;301:131-141. DOI: https://doi.org/10.1016/j.memsci.2007.06.007

Rahardianto A, Gao J, Gabelich CJ, Williams MD, Cohen Y. High recovery membrane desalting of low-salinity brackish water: Integration of accelerated precipitation softening with membrane RO. J. Membr. Sci. 2007;289:123-137. DOI: https://doi.org/10.1016/j.memsci.2006.11.043

Nadav N, Priel M, Glueckstern P. Boron removal from the permeate of a large SWRO plant in Eilat. Desalination 2005;185:121-129. DOI: https://doi.org/10.1016/j.desal.2005.03.075

Gaid K, Treal Y. Le dessalement des eaux par osmose inverse: l'expérience de Véolia Water. Desalination 2007;203:1-14. DOI: https://doi.org/10.1016/j.desal.2006.03.523

Glueckstern P, Priel M. Optimization of boron removal in old and new SWRO systems. Desalination 2003;156:219-228. DOI: https://doi.org/10.1016/S0011-9164(03)00344-8

Koseoglu H, Kabay N, Yüksel M, Sarp S, Arar Ö, Kitis M. Boron removal from seawater using high rejection SWRO membranes - impact of pH, feed concentration, pressure, and cross-flow velocity. Desalination 2008;227:253-263. DOI: https://doi.org/10.1016/j.desal.2007.06.029

Mane PP, Park PK, Hyung H, Brown JC, Kim JH. Modeling boron rejection in pilot- and full-scale reverse osmosis desalination processes. J. Membr. Sci. 2009;338:119-127. DOI: https://doi.org/10.1016/j.memsci.2009.04.014

Taniguchi M, Fusaoka Y, Nishikawa T, Kurihara M. Boron removal in RO seawater desalination. Desalination 2004;167:419-426. DOI: https://doi.org/10.1016/j.desal.2004.06.157

Huang H, Schwab K, Jacangelo JG. Pretreatment for low pressure membranes in water treatment: a review. Environ. Sci. Technol. 2009;43:3011-3019. DOI: https://doi.org/10.1021/es802473r

Múñoz Elguera A, Pérez Báez SO. Development of the most adequate pre-treatment for high capacity seawater desalination plants with open intake. Desalination 2005;184:173-183. DOI: https://doi.org/10.1016/j.desal.2005.04.033

O'Melia CR. Aquasols: the behavior of small particles in aquatic systems. Environ. Sci. Technol. 1980;14:1052-1060. DOI: https://doi.org/10.1021/es60169a601

Water desalination. Technical manual TM 5-813-8. Washington, DC: U.S. Department of the Army; 1986.

Peleka EN, Matis KA. Application of flotation as a pretreatment process during desalination. Desalination 2008;222:1-8.0 DOI: https://doi.org/10.1016/j.desal.2007.04.067

Rubio J, Souza ML, Smith RW. Overview of flotation as a wastewater treatment technique. Miner. Eng. 2002;15:139-155. DOI: https://doi.org/10.1016/S0892-6875(01)00216-3

Vedavyasan CV. Pretreatment trends - an overview. Desalination 2007;203:296-299. DOI: https://doi.org/10.1016/j.desal.2006.04.012

Pearce GK. The case for UF/MF pretreatment to RO in seawater applications. Desalination 2007;203:286-295. DOI: https://doi.org/10.1016/j.desal.2006.04.011

Choi YH, Kweon JH, Kim DI, Lee S. Evaluation of various pretreatment for particle and inorganic fouling control on performance of SWRO. Desalination 2009;247:137-147. DOI: https://doi.org/10.1016/j.desal.2008.12.019

Hamed OA. Overview of hybrid desalination systems – current status and future prospects. Desalination 2005;186:207-214. DOI: https://doi.org/10.1016/j.desal.2005.03.095

Van der Bruggen B, Vandecasteele C. Distillation vs. membrane filtration: overview of process evolutions in seawater desalination. Desalination 2002;143:207-218. DOI: https://doi.org/10.1016/S0011-9164(02)00259-X

Kamp PC, Kruithof JC, Folmer HC. UF/RO treatment plant Heemskerk: from challenge to full scale application. Desalination 2000;131:27-35. DOI: https://doi.org/10.1016/S0011-9164(00)90003-1

Pearce GK. UF/MF pre-treatment to RO in seawater and wastewater reuse applications: a comparison of energy costs. Desalination 2008;222:66-73. DOI: https://doi.org/10.1016/j.desal.2007.05.029

Teuler A, Glucina K, Laine JM. Assessment of UF pretreatment prior RO membranes for seawater desalination. Desalination 1999;125:89-96. DOI: https://doi.org/10.1016/S0011-9164(99)00126-5

Kimura K, Maeda T, Yamamura H, Watanabe Y. Irreversible membrane fouling in microfiltration membranes filtering coagulated surface water. J. Membr. Sci. 2008;320:356-362. DOI: https://doi.org/10.1016/j.memsci.2008.04.018

Wang J, Guan J, Santiwong SR, Waite TD. Characterization of floc size and structure under different monomer and polymer coagulants on microfiltration membrane fouling. J. Membr. Sci. 2008;321:132-138. DOI: https://doi.org/10.1016/j.memsci.2008.04.008

Howe KJ, Marwah A, Chiu KP, Adham SS. Effect of coagulation on the size of MF and UF membrane foulants. Environ. Sci. Technol. 2006;40:7908-7913. DOI: https://doi.org/10.1021/es0616480

Schäfer AI, Fane AG, Waite TD. Cost factors and chemical pretreatment effects in the membrane filtration of waters containing natural organic matter. Water Res. 2001;35:1509-1517. DOI: https://doi.org/10.1016/S0043-1354(00)00418-8

Lee J, Walker HW. Effect of process variables and natural organic matter on removal of microcystin-LR by PAC - UF. Environ. Sci. Technol. 2006;40:7336-7342. DOI: https://doi.org/10.1021/es060352r

Yoon Y, Westerhoff P, Snyder SA, Esparza M. HPLC-fluorescence detection and adsorption of bisphenol A, 17β-estradiol, and 17α-ethynyl estradiol on powdered activated carbon. Water Res. 2003;37:3530-3537. DOI: https://doi.org/10.1016/S0043-1354(03)00239-2

Najm IN, Snoeyink VL, Lykins BW, Adams JQ. Using powdered activated carbon - a critical review. J. Am. Water Works Assoc. 1991;83:65-76. DOI: https://doi.org/10.1002/j.1551-8833.1991.tb07087.x

Westerhoff P, Yoon Y, Snyder S, Wert E. Fate of endocrine-disruptor, pharmaceutical, and personal care product chemicals during simulated drinking water treatment processes. Environ. Sci. Technol. 2005;39:6649-6663. DOI: https://doi.org/10.1021/es0484799

Yoon Y, Westerhoff P, Snyder SA. Adsorption of 3H-labeled 17-β estradiol on powdered activated carbon. Water Air Soil Pollut. 2005;166:343-351. DOI: https://doi.org/10.1007/s11270-005-7274-z

Tien VN, Chaudhary DS, Ngo HH, Vigneswaran S. Arsenic in water: concerns and treatment technologies. J. Ind. Eng. Chem. 2004;10:337-348.

Yuasa A. Drinking water production by coagulation-microfiltration and adsorption-ultrafiltration. Water Sci. Technol. 1998;37:135-146. DOI: https://doi.org/10.2166/wst.1998.0394

Mauter MS, Elimelech M. Environmental applications of carbon-based nanomaterials. Environ. Sci. Technol. 2008;42:5843-5859. DOI: https://doi.org/10.1021/es8006904

Pan B, Xing B. Adsorption mechanisms of organic chemicals on carbon nanotubes. Environ. Sci. Technol. 2008;42:9005-9013. DOI: https://doi.org/10.1021/es801777n

Upadhyayula VK, Deng S, Mitchell MC, Smith GB. Application of carbon nanotube technology for removal of contaminants in drinking water: a review. Sci. Total Environ. 2009;408:1-13. DOI: https://doi.org/10.1016/j.scitotenv.2009.09.027

Crittenden J, Montgomery Watson Harza. Water treatment principles and design. 2nd ed. Hoboken: John Wiley; 2005. p. 75-90.

Vos G, Brekvoort Y, Oosterom HA, Nederlof MM. Treatment of canal water with ultrafiltration to produce industrial and household water. Desalination 1998;118:297-303. DOI: https://doi.org/10.1016/S0011-9164(98)00151-9

Plummer JD, Edzwald JK. Effects of chlorine and ozone on algal cell properties and removal of algae by coagulation. J. Water Supply Res. Technol. AQUA 2002;51:307-318. DOI: https://doi.org/10.2166/aqua.2002.0027

Wilczak A, Howe EW, Aieta EM, Lee RG. How peroxidation affects particle removal during clarification and filtration. J. Am. Water Works Assoc. 1992; 84:85-94. DOI: https://doi.org/10.1002/j.1551-8833.1992.tb05905.x

Hasan Al-Sheikh AH. Seawater reverses osmosis pretreatment with an emphasis on the Jeddah Plant operation experience. Desalination 1997; 110:183-192. DOI: https://doi.org/10.1016/S0011-9164(97)00096-9

Lorain O, Hersant B, Persin F, Grasmick A, Brunard N, Espenan JM. Ultrafiltration membrane pre-treatment benefits for reverse osmosis process in seawater desalting. Quantification in terms of capital investment cost and operating cost reduction. Desalination 2007; 203:277-285. DOI: https://doi.org/10.1016/j.desal.2006.02.022

HOANG T. T. L.2005.Granular Activated Carbon (GAC) Biofilter in Water and Wastewater Treatment. Master’s Thesis, University of Technology, Sydney GLOBAL WATER INTELLIGENCE 2006. The 19Th IDA World Wide Desalting Plant Inventory.

GLUCINA, K., LAINE, J. M. & DURAND-BOURLIER, L. 1998. Assessment of filtration mode for the ultrafiltration membrane process. Desalination, 18, 205-211. DOI: https://doi.org/10.1016/S0011-9164(98)00131-3

GLUECKSTERN, P., PRIEL, M. & WILF, M. 2002. Field evaluation of capillary UF technology as a pretreatment for large seawater RO systems. Desalination, 147, 55-62. DOI: https://doi.org/10.1016/S0011-9164(02)00576-3

GREENLEE, L. F., LAWLER, D. F., FREEMAN, B. D., MARROT, B. & MOULIN, P. 2009. Reverse osmosis desalination: Water sources, technology, and today's challenges. Water Research, 43, 2317-2348. DOI: https://doi.org/10.1016/j.watres.2009.03.010

GUIDA, M., MATTEI, M., DELLA ROCCA, C., MELLUSO, G. & MERIÇ, S. 2007. Optimization of alum-coagulation/flocculation for COD and TSS removal from five municipal wastewater. Desalination, 211, 113-127. DOI: https://doi.org/10.1016/j.desal.2006.02.086

GUO, W. S., VIGNESWARAN, S., NGO, H. H. & CHAPMAN, H. 2004. Experimental investigation of adsorption–flocculation–microfiltration hybrid system in wastewater reuse. Journal of Membrane Science, 242, 27-35. DOI: https://doi.org/10.1016/j.memsci.2003.06.006

HEDGES, J. I. 1987. Organic matter in sea water. Nature, 330, 205-206. DOI: https://doi.org/10.1038/330205a0

HOANG, T., VIGNESWARAN, S., NGO, H., KANDASAMY, J., SHIM, W., CHAUDHARY, D., GOTETY, P. & PEIRIS, P. 2008. Performance evaluation and mathematical modelling of granular activated carbon biofiltration in wastewater treatment. Korean Journal of Chemical Engineering, 25, 259-267. DOI: https://doi.org/10.1007/s11814-008-0046-x

Downloads

Published

Issue

Section

Categories

License

Copyright (c) 2024 Zinah A. Alshrefy , Huda T. Hamad, Shahad Al-Najjar, Zainab T. Al-Sharify (Author)

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Open Access and Copyright: SETS operates as an open-access journal, making all its articles freely available to everyone. Published content is licensed under the Creative Commons Attribution International Public License (CC BY 4.0). This license allows individuals and organizations to:

- Download, share, distribute, and print full texts of articles

- Reproduce or link to articles in any medium,

While authors retain copyright for their published work on the SETS website, the journal actively promotes and tracks citations to increase recognition for their research.

In essence, CC-BY-4.0 encourages the widest possible dissemination and utilization of published articles as long as written permission and appropriate credit are given to the authors.