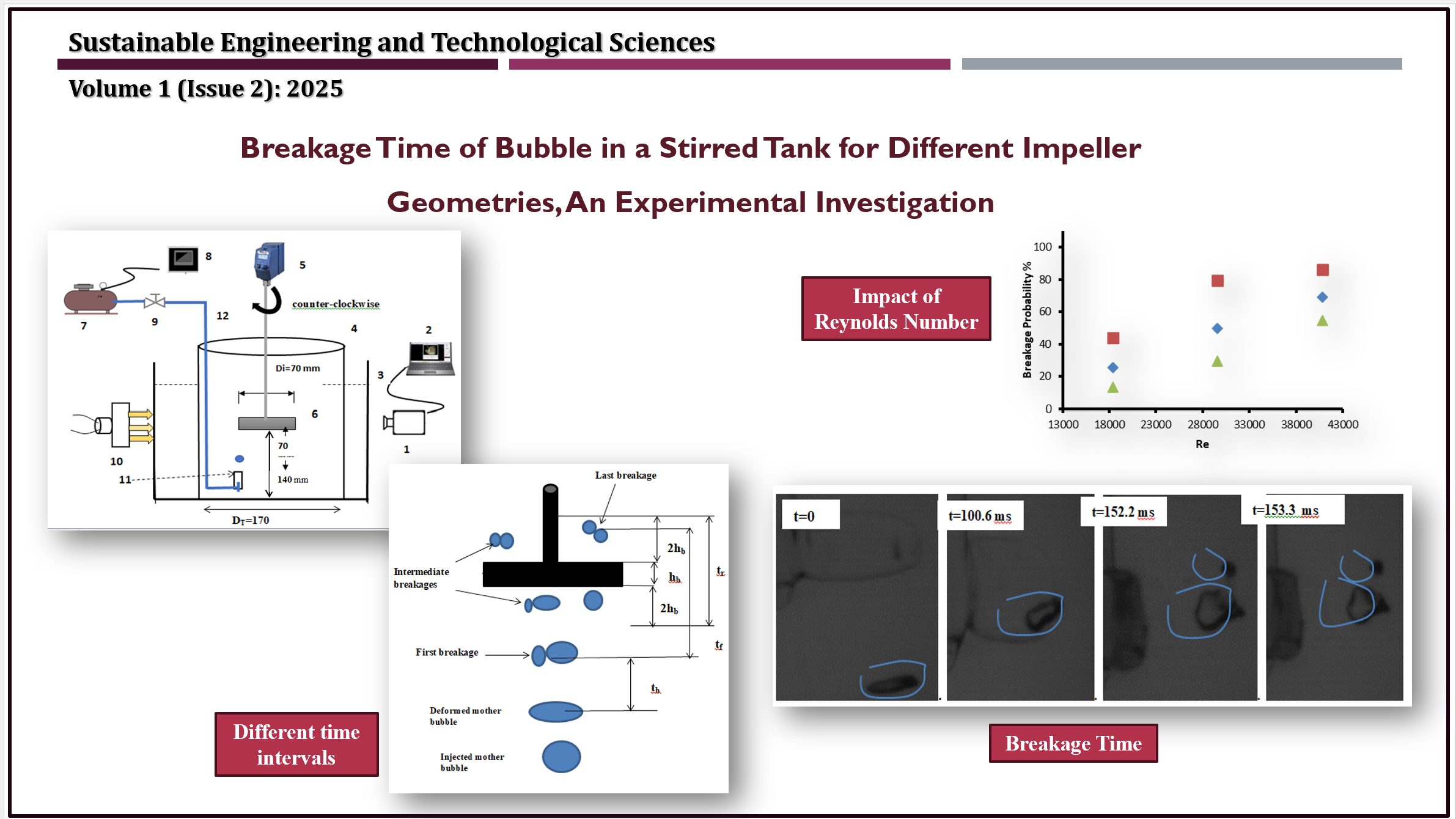

Breakage Time of Bubble in a Stirred Tank for Different Impeller Geometries, An Experimental Investigation

DOI:

https://doi.org/10.70516/8tk3qp78Keywords:

Breakup Time, Impeller Geometry, Stirred Tank, Breakup Probability, Birth RateAbstract

The successful tank stirring operation requires extensive studies for selecting a suitable impeller design for the dispersion processes in such systems. In this context, the effects of impeller geometry and Reynolds number (Re) on bubble breakage time were investigated to gain a deeper understanding of the breakage phenomena. Three different impeller geometries were investigated: a 4-Twisted blades impeller (4TB), a 4-Flat blades impeller (4FB), and a 2-Flat blades impeller (2FB) For Re range of 18380 to 40830 (based on impeller diameter). Three different time intervals were recognized during the mother bubble’s motion; initial breakage time, final breakage time, and retention time. The initial and final breakage times were calculated by following the injected bubble using a high speed camera at different zones around and in the impeller region. It was found that the breakage time decreases with increasing Reynolds number (or stirring speed) for all geometries. The 4-Flat blades impeller showed the lowest breakage time indicating the highest breakage rate. For 4-FB impeller, it decreases by about 20% when the Re increases from 18380 to 40830. The breaking interval increases with increasing Re and is lowest for 4FB impeller. The increase is for 4FB is 65%.

Downloads

References

B.O. Hasan, M. F. Hamad, H. Sh. Majdi, M. M. Hathal, Experimental characterization of dynamic behavior of single bubble breakage in an agitated tank, European Journal of Mechanics / B Fluids .85 (2021) 430–443. https://doi.org/10.1016/j.euromechflu.2020.11.001 DOI: https://doi.org/10.1016/j.euromechflu.2020.11.001

H. Zhou, X. Yu, B. Wang, S. Jing, W. Lan, S. Li, Experimental study on drop breakup time and breakup rate with drop swarms in a stirred tank, AIChE J. 27(2021) 1–21. https://doi.org/10.1002/aic.17065 DOI: https://doi.org/10.1002/aic.17065

R. Andersson, B. Andersson, Modeling the breakup of fluid particles in turbulent flows ,AIChE, J. 52(2006) 2031–2038. https://doi.org/10.1002/aic.10832 DOI: https://doi.org/10.1002/aic.10832

B.O. Hasan, Experimental study on the bubble breakage in a stirred tank Part 1: Mechanism and effect of operating parameters, International Journal of Multiphase Flow 97(2017a) 94–108. https://doi.org/10.1016/j.ijmultiphaseflow.2017.08.006

B.O. Hasan, Experimental study on the bubble breakage in a stirred tank, Part 2: local dependence of breakage events, Exp. Therm. Fluid Sci. 96 (2018)48–62. https://doi.org/10.1016/j.expthermflusci.2018.02.013 DOI: https://doi.org/10.1016/j.expthermflusci.2018.02.013

H. Hartmanna, J. J. Derksen, C. Montavonb, J. Pearsonb, I. S. Hamillb, van den Akker H E A. Assessment of large eddy and RANS stirred tank simulations by means of LDA, Chem. Eng. Sci. 59 (2004)2419–2432. https://doi.org/10.1016/j.ces.2004.01.065 DOI: https://doi.org/10.1016/j.ces.2004.01.065

A. Zamiri, J. T. Chung, Numerical evaluation of turbulent flow structures in a stirred tank with a Rushton turbine based on scale-adaptive simulation Computers & Fluids 170(2018)236–248. https://doi.org/10.1016/j.compfluid.2018.05.007 DOI: https://doi.org/10.1016/j.compfluid.2018.05.007

J. Ramírez-Cruz, M. Salinas-Vázquez, G. Ascanio, W. Vicente-Rodríguez, C. Lagarza-Córtes, Mixing dynamics in an uncovered unbaffled stirred tank using Large- Eddy Simulations and a passive scalar transport equation, Chemical Engineering Science, 222(2020)115658. https://doi.org/10.1016/j.ces.2020.115658 DOI: https://doi.org/10.1016/j.ces.2020.115658

M. S. N. Oliveira, A. W. Fitch, X. NI. A study of bubble velocity and bubble residence time in a gassed oscillatory baffled column, Effect of Oscillation Frequency, Trans IChemE, Vol. 81, Part A, (2003) 233-242. https://doi.org/10.1205/026387603762878692 DOI: https://doi.org/10.1205/026387603762878692

B.O. Hasan, F. Krakau, Experimental study on the bubble breakage in a stirred tank. Part 1. Mechanism and effect of operating parameters Int. J. Multiph. Flow 97(2017) 94–108. https://doi.org/10.1016/j.ijmultiphaseflow.2017.08.006 DOI: https://doi.org/10.1016/j.ijmultiphaseflow.2017.08.006

H.A. Alabdly , H. Sh. Majdi, M. F. Hamad, M. M. Hathal, B.O. Hasan, Effect of impeller geometry on bubble breakage and the contributions of different breakage mechanisms in a stirred tank, Fluid Dyn. Res., 52(2020) 1–24. https://doi.org/10.1088/1873-7005/abbe97 DOI: https://doi.org/10.1088/1873-7005/abbe97

E. Herø, H. Forgia, J. Solsvik, H. A. Jakobsen, Single drop breakage in turbulent flow: Statistical data analysis, Chemical Engineering Science: X8(2020) 100082. https://doi.org/10.1016/j.cesx.2020.100082 DOI: https://doi.org/10.1016/j.cesx.2020.100082

Maluta, F., Hydrodynamics, power consumption and bubble size distribution in gas-liquid stirred tanks, Chemical Engineering Research and Design, 194 (2023) 582–596. https://doi.org/10.1016/j.cherd.2023.05.006 DOI: https://doi.org/10.1016/j.cherd.2023.05.006

J. Solsvik, H. Jakobsen, Single drop break up experiments in stirred liquid–liquid tank, Chem. Eng. Sci. 131 (2015a) 219–234. https://doi.org/10.1016/j.ces.2015.03.059 DOI: https://doi.org/10.1016/j.ces.2015.03.059

V. Hancil, V. Rod, Break-up of a drop in a stirred tank, Chem. Eng. Process. 23(1998) 189–193. https://doi.org/10.1016/0255-2701(88)80015-1 DOI: https://doi.org/10.1016/0255-2701(88)80015-1

S. Maass, A. Gabler, A. Zaccone, A. Paschedag, M. Kraume, Experimental investigations and modeling of breakage phenomena in stirred liquid/liquid systems, Chem. Eng. Res. Des. Trans. IChemE A 85 (A5) (2007) 703–709. https://doi.org/10.1205/cherd06187 DOI: https://doi.org/10.1205/cherd06187

M. Stork, Model-based Optimization of the Procedure of Emulsification, PhD thesis, Technical University Delft, Netherlands, 2005.

S. Maass, M. Kraume, Determination of breakage rates using single drop experiments, Chem. Eng. Sci. 70 (2012) 146–164. https://doi.org/10.1016/j.ces.2011.08.027 DOI: https://doi.org/10.1016/j.ces.2011.08.027

Y. Shuai, X.Wang, Z. Huang, J. Sun, Y. Yang, Experimental measurement of bubble breakup in a jet bubbling reactor, AIChE Journal, 67(2021) 1. https://doi.org/10.1002/aic.17062 DOI: https://doi.org/10.1002/aic.17062

M. Martin, F. Montes J, M. Gal’an, Bubbling process in stirred tank reactors I: agitator effect on bubble size, formation and rising Chem. Eng. Sci. 63 (2008a) 3212–3222. https://doi.org/10.1016/j.ces.2008.03.028 DOI: https://doi.org/10.1016/j.ces.2008.03.028

B. Prakash, T. S. Milinkumar, V. K. Pareek, R. P. Utikar, Impact of HSPBT blade angle on gas phase hydrodynamics in a gas–liquid stirred tank, Chemical Engineering Research and Design 130 (2018)219–229. https://doi.org/10.1016/j.cherd.2017.12.028 DOI: https://doi.org/10.1016/j.cherd.2017.12.028

D. Mesa, R. Pablo, Brito-Parada, Bubble size distribution in aerated stirred tanks: Quantifying the effect of impeller-stator design, Chemical Engineering Research and Design 160(2020) 356–369. https://doi.org/10.1016/j.cherd.2020.05.029 DOI: https://doi.org/10.1016/j.cherd.2020.05.029

M. Martin, F. Montes, M. Galan, Influence of impeller type on the bubble breakup process in stirred tanks, Ind. Eng. Chem. Res. 47(2008b) 6251–6263. https://doi.org/10.1021/ie800063v DOI: https://doi.org/10.1021/ie800063v

C. Bliatsiou, A. Malik, L. Böhm, M. Kraume, Influence of Impeller Geometry on Hydromechanical Stress in Stirred Liquid/Liquid Dispersions, Ind. Eng. Chem. Res., 58(2019) 2537−2550. https://doi.org/10.1021/acs.iecr.8b03654 DOI: https://doi.org/10.1021/acs.iecr.8b03654

S. M. Harriott (). Unit Operations of Chemical Engineering 6th ed., McGraw-Hill International, New York, 2001.

B.O. Hasan, M.A Sahir.. Corrosion of carbon steel in two phase flow (CO2 gas-CaCO3 solution) controlled by sacrificial anode, Journal of Natural Gas Science and Engineering, 46(2017) 71-79. https://doi.org/10.1016/j.jngse.2017.06.032 DOI: https://doi.org/10.1016/j.jngse.2017.06.032

C.A. Coulaloglou, L.L. Tavlarides, Description of interaction processes in agitated liquid–liquid dispersions. Chem. Eng. Sci. 32 (11) (1977) 1289–1297. https://doi.org/10.1016/0009-2509(77)85023-9 DOI: https://doi.org/10.1016/0009-2509(77)85023-9

M. Konno, A. Aoki, S. Saito, Scale effect on breakup process in liquid-liquid agitated tanks. J. Chem. Eng. Jpn. 16 (4) (1983) 312–319. https://doi.org/10.1252/jcej.16.312 DOI: https://doi.org/10.1252/jcej.16.312

Downloads

Published

Issue

Section

Categories

License

Copyright (c) 2024 Muayad F. Hamad, Basim O. Hasan, Hasan Sh. Majdi, Abbas Al-Farraji (Author)

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Open Access and Copyright: SETS operates as an open-access journal, making all its articles freely available to everyone. Published content is licensed under the Creative Commons Attribution International Public License (CC BY 4.0). This license allows individuals and organizations to:

- Download, share, distribute, and print full texts of articles

- Reproduce or link to articles in any medium,

While authors retain copyright for their published work on the SETS website, the journal actively promotes and tracks citations to increase recognition for their research.

In essence, CC-BY-4.0 encourages the widest possible dissemination and utilization of published articles as long as written permission and appropriate credit are given to the authors.